Cuts precise notches in plastic/non-metallic samples for impact tests per standards.

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

Product Introduction:

Plastic electric notch prototype is a cantilever beam, simply supported beam impact testing machine to do the impact toughness test of non-metallic materials used in the notch sample sample production equipment, impact notch prototype equipment can be used in scientific research institutions, colleges and universities, non-metallic materials production plants and other units of the laboratory to make notch samples.

Reference standard:

ISO 180-2000 "Plastics - Determination of impact strength of rigid cantilever beams"

GB/T 1843-2008 "Rigid plastic cantilever beam impact test method"

JB/T 8761-1998 "Plastic Cantilever beam Impact Testing Machine"

ASTM D256-2010 "Test Method for Determining the Impact Strength of IZOD Pendulus in Plastics"

ISO 179-2000 "Plastics - Determination of impact strength of simple supported beams of Hard materials"

GB/T 1043-2008 "Rigid plastic simple supported beam impact test method"

JB/T 8762-1998 "Plastic Simply supported beam Impact Testing Machine"

Product Advantages:

Produces Standardized Samples: Creates notches in test specimens with precise dimensions and geometry as required by international and national impact testing standards.

Essential for Accurate Impact Testing: Proper notching is critical for obtaining reliable and repeatable impact strength results.

Standard Compliant: Designed to prepare samples conforming to specific sample and notch types defined in standards like ISO 180. ISO 179. ASTM D256. GB/T 1843. and GB/T 1043.

Versatile for Materials: Suitable for preparing notched samples from various rigid plastics and other non-metallic materials.

Electric Operation: Provides controlled and consistent notch cutting compared to manual methods.

Supports Multiple Sample and Notch Types: Can produce specimens for different impact test methods and requirements.

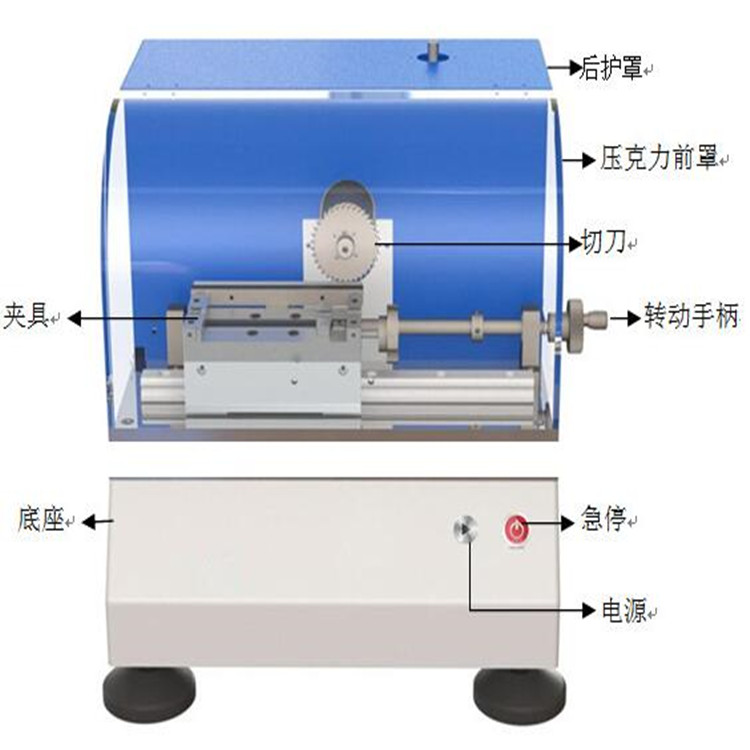

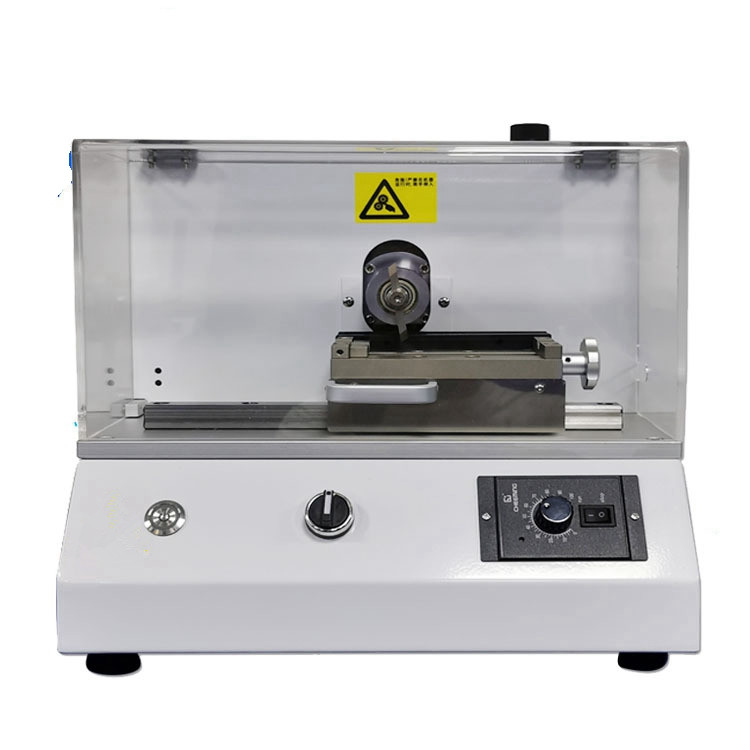

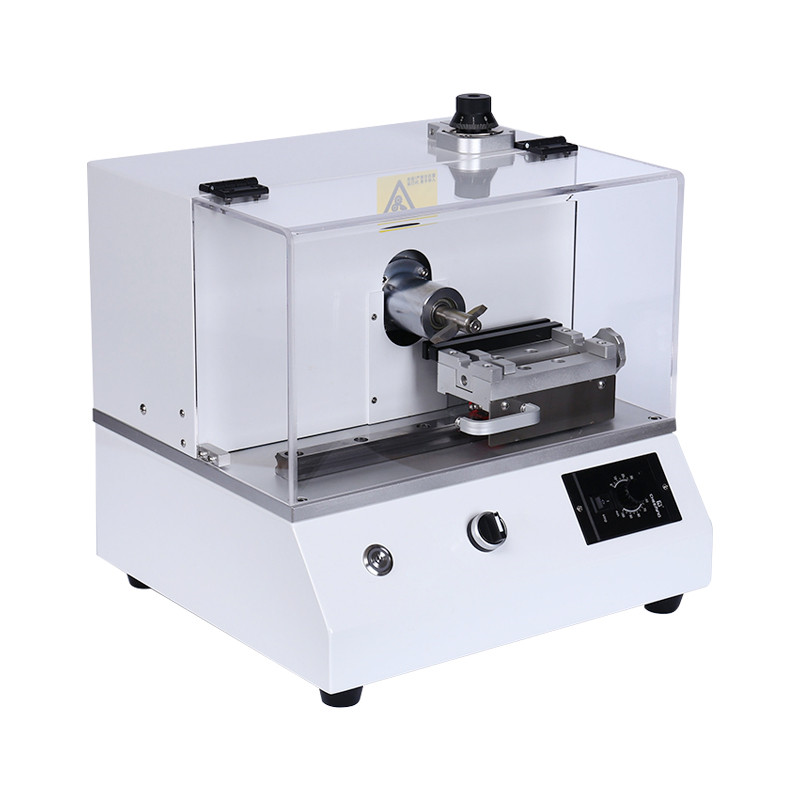

Product Features:

Mechanism for securely holding test specimens during the notching process.

A precise cutting tool or blade specifically designed for creating the required notch geometry (different blades for Type A, B, C notches).

Controlled feed speed of the cutting tool or sample (30 mm/min) to ensure consistent notch quality.

Table or cutting mechanism with a specified stroke (>160mm) to accommodate sample length.

Capability to prepare specimens according to different sample types (Type 1. 2. 3) as defined in impact testing standards.

Capability to produce different notch types (Type A, with Type B and C as options) by using appropriate cutting tools.

Electric motor and control system for automated or semi-automated notching.

Robust and stable construction to ensure the precision of the notch geometry.

Technical parameters:

Table stroke: >160mm

Feed speed: 30mm/min

Sample type: Type 1, type 2, type 3

Notch type: Type A, Type B (optional), Type C (optional)

Disclaimer: Le contenu ci-dessus est destiné à des fins de référence et de communication uniquement entre les initiés de l'industrie, et ne garantit pas son exactitude ou son exhaustivité. Conformément aux lois et règlements pertinents et aux règlements de ce site Web, les unités ou personnes qui achètent des articles connexes doivent obtenir des qualifications et des conditions de qualification valides.

Téléphone de l'entreprise

+86-21-6420 0566

Heures de travail

Du lundi au vendredi

Téléphone portable:

13816217984

Courriel :

info@qinsun-lab.com