Heure : Popularité :0Le temps

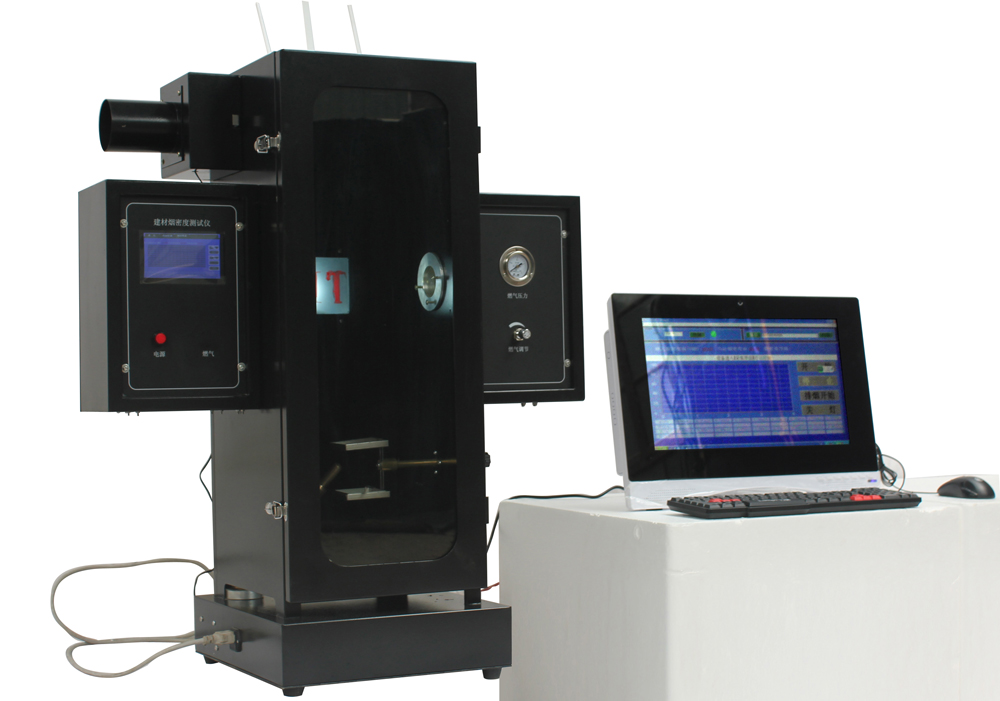

The instrument uses both touch screen and computer control modes, and is equipped with automatic ignition, timing, and smoke exhaust functions. It uses a silicon photocell sensor to measure the attenuation of the light source by combustion smoke. The measurement range covers 0-100% smoke density and the accuracy can reach ±3%.

1. Turn on the device power and light source.

2. Open the Phoenix PC software, open the Optical Path Calibration page, click Optical Path Calibration, and perform three filter calibrations (0%, 100%, and 50%).

3. Open the gas source and the gas and air ball valves (main gas, main air, auxiliary gas, and auxiliary air). Check and adjust the pressures. The main pressure is 0.276 MPa and the auxiliary pressure is 0.138 MPa.

4. Verify the flames. The main and auxiliary flames should be blue impingement flames.

5. Place the specimen, close the chamber door, and lower the damper.

6. Click the main ignition button, click Start Test, and insert the specimen. Combustion begins.

7. The test timer begins.

8. The device automatically shuts down after 240 seconds.

9. Perform three tests.

10. After the test is complete, raise the damper back up and click the exhaust fan button to start exhausting.

11. Save the test data, click Exit, generate a report, and import the three test data into a folder. Finally, generate the report and exit.

12. Turn off the power and gas after the test.

1. Regular Cleaning to Ensure Instrument Accuracy

Cleaning a smoke density meter is a crucial part of maintenance. Dust, oil, or material left over from the test process inside and outside the instrument can interfere with test results and affect the instrument's accuracy. Therefore, operators should regularly use a soft cloth or cleaning tool to gently wipe the instrument housing and sensor surface to avoid scratches. Clean the air passages, sensors, and detection devices inside the instrument according to the instrument's manual to ensure proper functioning.

2. Checking and Calibrating the Sensor

The smoke density meter's sensor is one of its core components. Sensor accuracy directly affects the reliability of test data. Therefore, regular inspection of the sensor's operating condition is crucial. If inaccurate measurements are detected, calibration should be performed immediately. The frequency of calibration is typically determined by the instrument's usage frequency and the manufacturer's recommendations. During calibration, standardized test samples should be used to ensure accurate measurement data each time.

3. Checking the Power System and Battery Condition

Smoke density meters are typically powered by batteries or an external power supply. During maintenance, inspecting the power system is essential. First, check that the battery is in working order. If it's low, replace it promptly. Also, ensure that the power cord, plug, and other components are intact. If the device has not been used for an extended period, consider removing the battery to prevent leakage and damage to the internal circuitry.

4. Regularly Update Software and Firmware

Most modern smoke density meter instruments come with specialized software and firmware to assist with data analysis and storage. Therefore, keeping these software and firmware up to date is crucial. Manufacturers often release new software and firmware upgrades to improve device functionality or address known vulnerabilities. Operators should regularly check for manufacturer update notifications and follow the prescribed procedures to perform software updates to ensure optimal device operation.

5. Proper Storage and Protection

Storing and protecting the smoke density meter is equally important. The device should be stored in a dry, temperature-controlled environment, avoiding exposure to moisture, heat, or strong vibration, as these factors can accelerate aging and damage. During transportation and storage, use a shock-resistant protective case or specialized packaging to minimize external impact.

6. Regularly perform a comprehensive inspection. To ensure the smoke density meter is always in optimal working condition, it's recommended to perform a comprehensive inspection periodically. This includes checking all functions, software updates, and sensor status. Regular comprehensive inspections can identify potential issues and prevent delays or inaccurate data due to equipment failure.

Téléphone de l'entreprise

+86-21-6420 0566

Heures de travail

Du lundi au vendredi

Téléphone portable:

13816217984

Courriel :

info@qinsun-lab.com