I. Product Overview The Fleece Loop Length Tester is a specialized instrument designed to measure t

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

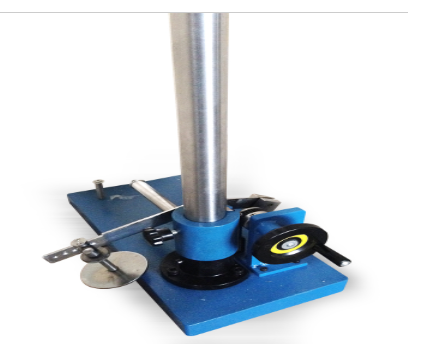

I. Product Overview

The Fleece Loop Length Tester is a specialized instrument designed to measure the fiber loop length distribution in fleece fabrics, critical for evaluating softness, bulkiness, and durability. It utilizes non-contact laser scanning technology to ensure precise and repeatable measurements aligned with international textile standards.

| Paramètres | Specifications |

|---|---|

| Measurement Principle | Laser micrometer + AI pattern recognition |

| Resolution | ±0.5 μm (ISO 137 standard validation) |

| Sample Size | 100×100mm (adjustable clamping frame) |

| Scanning Speed | 300 mm/s (full-area mapping) |

| Power Supply | 220V/50Hz, 0.8kW |

| Dimensions | 500×400×700mm (W×D×H) |

Disclaimer: Le contenu ci-dessus est destiné à des fins de référence et de communication uniquement entre les initiés de l'industrie, et ne garantit pas son exactitude ou son exhaustivité. Conformément aux lois et règlements pertinents et aux règlements de ce site Web, les unités ou personnes qui achètent des articles connexes doivent obtenir des qualifications et des conditions de qualification valides.

Téléphone de l'entreprise

+86-21-6420 0566

Heures de travail

Du lundi au vendredi

Téléphone portable:

13816217984

Courriel :

info@qinsun-lab.com